Innovative Strategies and Unmatched Quality from Premier Injection Mold Manufacturers at DeepMould.net

In the dynamic world of metal fabrication, injection mold manufacturers play a pivotal role in transforming raw materials into complex, precision-engineered components. These manufacturers are at the forefront of technological innovation, combining advanced manufacturing techniques, cutting-edge materials, and expert craftsmanship to deliver outstanding results for a diverse range of industries including automotive, consumer electronics, healthcare, and aerospace.

Why Choose DeepMould.net as Your Trusted Injection Mold Manufacturer?

At DeepMould.net, we have established ourselves as a leader in the field of injection mold manufacturing. Our dedication to quality, innovation, and customer satisfaction sets us apart from traditional providers. Here’s why partnering with us can elevate your manufacturing processes:

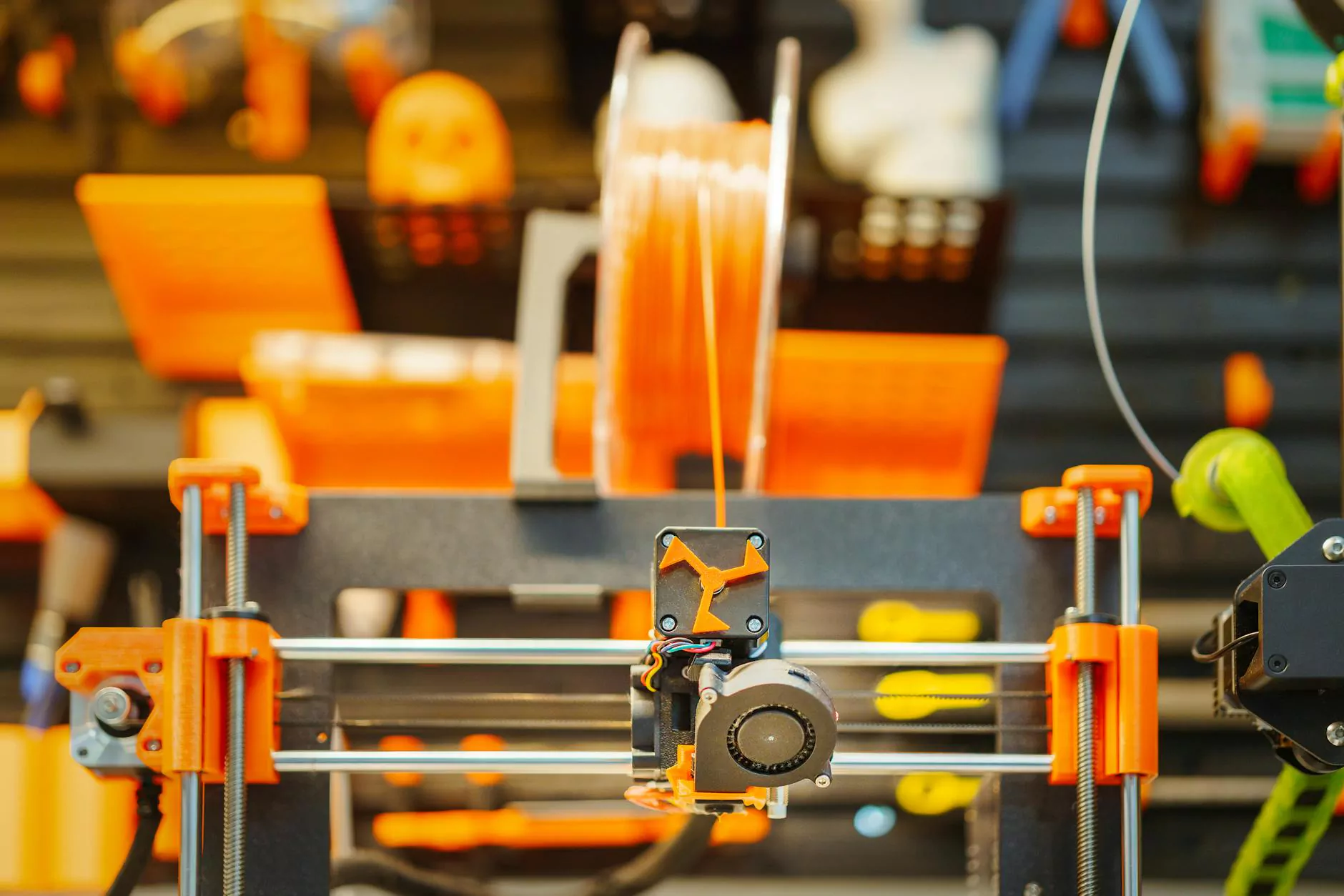

- Unparalleled Precision and Quality: Our state-of-the-art facilities utilize the latest CNC machining, EDM, and 3D printing technologies to produce molds with pinpoint accuracy, ensuring impeccable final product quality.

- Experience and Expertise: With decades of combined industry knowledge, our team of engineers and technicians design and produce molds that meet stringent specifications and standards.

- Customized Solutions: We understand that each project has unique demands. Our team offers tailored mold design and manufacturing services to match specific requirements, materials, and production volumes.

- Fast Turnaround Times: Leveraging advanced workflow management and logistics, we ensure prompt delivery without compromising quality, keeping your projects on schedule.

- Competitive Pricing: Our efficient manufacturing processes and bulk procurement strategies allow us to offer cost-effective solutions, maximizing your ROI.

- End-to-End Support: From initial concept through to final production, we provide comprehensive support including prototyping, testing, and ongoing maintenance.

The Role of Injection Mold Manufacturers in Modern Metal Fabrication

Injection mold manufacturers are fundamental to the metal fabrication chain, particularly in producing high-precision metal parts used across various sectors. Their core competencies include designing durable molds capable of withstanding high-volume production, managing complex geometries, and maintaining tight tolerances.

These manufacturers employ a range of advanced manufacturing methods such as:

- Precision CNC Machining: Ensures molds are crafted with micron-level accuracy for intricate details and fine features.

- Electrical Discharge Machining (EDM): Enables the creation of complex cavities and fine features impossible with conventional methods.

- 3D Printing and Additive Manufacturing: Used in rapid prototyping and designing complex mold components to accelerate development cycles.

- Surface Treatments and Coatings: Applied to improve mold longevity, reduce wear, and facilitate easy release of molded parts.

Materials Used by Leading Injection Mold Manufacturers

Top injection mold manufacturers select their materials meticulously to ensure durability, thermal stability, and ease of maintenance. Commonly used materials include:

- Hardened Steel: For high-volume, long-term production, offering excellent wear resistance.

- P20 Steel: Popular for its ease of machining and good toughness, suitable for medium to high-volume production.

- Aluminum Alloys: Ideal for prototypes and short-run manufacturing due to lightweight and quicker machining capabilities.

- Stainless Steel: Used where corrosion resistance and hygiene are critical, such as in medical or food-grade applications.

Design and Development of High-Performance Injection Molds

Effective injection mold manufacturers employ sophisticated design techniques to optimize mold performance. This includes:

- CAD/CAM Integration: Utilization of computer-aided design and manufacturing software allows for detailed modeling and simulation to predict mold behavior and identify potential issues before machining.

- Finite Element Analysis (FEA): Used to analyze stress distributions, thermal behaviors, and material flow, ensuring mold longevity and quality.

- Prototyping and Testing: Rapid prototyping accelerates design validation and allows for iterative improvements to ensure optimal function.

- Collaborative Design Approach: Working closely with clients, our team ensures molds are designed with manufacturability and efficiency in mind, reducing costly revisions and production delays.

Quality Assurance and Certification in Injection Mold Manufacturing

Quality assurance is a core pillar for injection mold manufacturers aiming for excellence. At DeepMould.net, we adhere to international standards such as ISO 9001, ISO 13485, and other industry-specific certifications. Our rigorous QA processes include:

- Comprehensive inspection at every manufacturing stage

- Dimensional accuracy verification using Coordinate Measuring Machines (CMM)

- Material testing to ensure compliance with specifications

- Functional testing of molds prior to delivery

- Post-production support and continuous improvement strategies

Industries That Rely on Top Injection Mold Manufacturers

The versatility and precision of high-quality injection molds make them essential across numerous sectors:

- Automotive: Manufacturing complex and durable components like gears, housings, and interior parts.

- Electronics: Producing small, intricate parts for devices, connectors, and casings with tight tolerances.

- Medical Devices: Creating sterilizable, high-precision implants and surgical tools.

- Consumer Goods: Crafting a broad array of plastic and metal parts for everyday products.

- Aerospace: Developing lightweight, high-strength metal components capable of withstanding extreme conditions.

Future Trends and Innovations in Injection Mold Manufacturing

As technology advances, injection mold manufacturers are embracing innovations to further enhance productivity, quality, and sustainability:

- Smart Manufacturing: Incorporating IoT and automation for real-time monitoring and predictive maintenance.

- Green Manufacturing: Using eco-friendly materials and recycling waste to minimize environmental impact.

- Rapid Prototyping Integration: Accelerating product development cycles with rapid mold fabrication techniques.

- Artificial Intelligence (AI) and Machine Learning: Optimizing design, process control, and quality management through advanced analytics.

Partnering with DeepMould.net for Superior Metal Fabrication

Whether you need a single prototype or large-volume production, partnering with DeepMould.net ensures you receive comprehensive, high-quality services from start to finish. Our commitment to excellence and innovation ensures your projects are executed with precision, speed, and cost-efficiency.

Conclusion: Elevate Your Production Capabilities with the Right Injection Mold Manufacturer

The choice of an injection mold manufacturer significantly influences the success of your manufacturing endeavors. By collaborating with industry leaders like DeepMould.net, you gain access to cutting-edge technology, expert craftsmanship, and unwavering commitment to quality. Our integrated approach, from design to delivery, ensures your products meet the highest standards in performance and durability.

Embrace the future of metal fabrication with our innovative solutions and set your business apart in a competitive marketplace. Trust DeepMould.net — your partner in excellence in injection mold manufacturing.